High-Quality Wood Milling Machine for Precision Woodworking

By:Admin

{Company name} is a prominent player in the manufacturing industry, known for its innovative and high-quality machinery. With a strong focus on precision, efficiency, and durability, {Company name} is dedicated to providing solutions that meet the needs of wood processing businesses.

For over [number of years] years, {Company name} has been at the forefront of developing cutting-edge technology for the woodworking industry. The company's commitment to research and development has allowed it to consistently deliver state-of-the-art machinery that optimizes production processes and enhances output quality.

The {Company name} team comprises industry experts, engineers, and professionals who are deeply passionate about fulfilling the demands of wood processing businesses. Their expertise and dedication have positioned {Company name} as a trusted partner for companies seeking reliable and advanced machinery solutions.

[News Content]

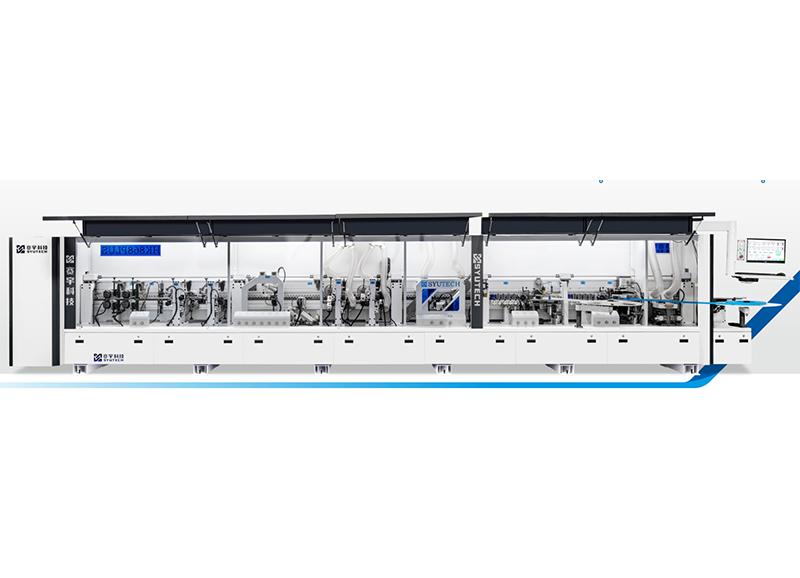

In the ever-evolving woodworking industry, the demand for advanced machinery that can streamline production processes and improve overall efficiency is constantly on the rise. Responding to this need, {Company name} has recently introduced its latest innovation - a cutting-edge milling machine designed specifically for wood processing applications.

The new milling machine, which has been developed after extensive research and testing, represents a significant leap forward in wood processing technology. Equipped with state-of-the-art features and capabilities, the machine is set to revolutionize the way wood is milled and processed, offering unprecedented levels of precision, speed, and reliability.

One of the key highlights of the new milling machine is its advanced automation capabilities. The machine is designed to significantly reduce the need for manual intervention, thereby optimizing the production process and minimizing the margin of error. This not only enhances operational efficiency but also helps in maximizing output while maintaining consistently high-quality standards.

Furthermore, the milling machine is equipped with a range of cutting tools and configurations, allowing for a high degree of customization to meet specific wood processing requirements. Whether it's milling, shaping, or carving, the machine's versatility makes it a highly adaptable and valuable asset for businesses involved in wood processing.

In addition to its advanced technical features, the new milling machine is also designed with user-friendliness in mind. {Company name} has placed a strong emphasis on creating an intuitive interface and control system, making it easy for operators to understand and operate the machine efficiently. This focus on usability is aimed at ensuring a seamless integration of the milling machine into existing production workflows.

With sustainability being a growing concern across industries, the new milling machine from {Company name} also incorporates eco-friendly features. From energy-efficient operation to reduced material wastage, the machine is designed to align with the principles of environmental responsibility, offering a greener approach to wood processing.

The introduction of this groundbreaking milling machine is a testament to {Company name}'s ongoing commitment to innovation and excellence. It underscores the company's dedication to empowering wood processing businesses with cutting-edge technology that can drive productivity, profitability, and overall growth.

As the woodworking industry continues to evolve, {Company name} remains at the forefront, leveraging its expertise and resources to develop solutions that address the ever-changing needs of the market. The new milling machine stands as a testament to the company's vision and capability to lead the way in shaping the future of wood processing technology.

In conclusion, {Company name}'s new milling machine is poised to make a significant impact in the woodworking industry, offering a compelling blend of advanced technology, operational benefits, and environmental sustainability. As businesses increasingly seek to optimize their wood processing operations, this innovative machinery solution presents a compelling opportunity to elevate productivity and achieve new levels of performance.

Company News & Blog

Innovative Circular Saw Attachment for Quick and Clean Cutting

[Company Introduction]Established in 1995, our company has been a leading manufacturer of cutting tools and equipment for the construction and automotive industries. With a focus on innovation and quality, we have continuously improved and expanded our product range to meet the evolving needs of our customers. Our commitment to providing reliable and efficient tools has earned us a solid reputation in the market, and we take pride in being a trusted partner for professionals and DIY enthusiasts alike.[News Content]Introducing the Revolutionary Drill Bit Circular SawIn line with our commitment to innovation and quality, we are thrilled to introduce the latest addition to our product line - the revolutionary Drill Bit Circular Saw. This cutting-edge tool is designed to streamline the cutting process, making it faster, more precise, and incredibly efficient.The Drill Bit Circular Saw is engineered to handle a wide range of cutting tasks, from woodworking to metal fabrication. The unique design allows it to seamlessly transition from drilling to cutting, eliminating the need for multiple tools and reducing downtime on the job. With its versatile functionality, this tool is a game-changer for professionals who demand high-performance equipment to get the job done.Key Features of the Drill Bit Circular Saw:1. Versatility: The Drill Bit Circular Saw is capable of cutting through various materials, including wood, metal, plastic, and more. Its adaptability makes it a valuable asset for professionals working on diverse projects.2. Efficiency: With its rapid cutting speed and precision, the Drill Bit Circular Saw significantly reduces the time and effort required to complete cutting tasks. This allows professionals to boost productivity without compromising on the quality of their work.3. Durability: Constructed from high-quality materials, the Drill Bit Circular Saw is built to withstand the demands of rigorous job sites. Its robust design ensures long-lasting performance, making it a reliable tool for professionals who rely on consistent results.4. Ease of Use: The ergonomic design of the Drill Bit Circular Saw prioritizes user comfort and control. Its intuitive features and adjustable settings empower professionals to work with confidence and precision.Customer Feedback:"I have been using the Drill Bit Circular Saw for a few weeks now, and I am impressed by its performance. It has simplified my workflow and allowed me to tackle a wider range of cutting tasks with ease. This tool is a game-changer for my business!" - Mark, Construction Contractor"I appreciate the versatility and reliability of the Drill Bit Circular Saw. It has become an essential tool in my workshop, and I highly recommend it to anyone in need of a powerful cutting solution." - Sarah, Woodworking EnthusiastWith the introduction of the Drill Bit Circular Saw, we continue to uphold our reputation for delivering cutting-edge tools that empower professionals to achieve exceptional results. As we strive to anticipate and address the evolving needs of the market, our commitment to innovation remains unwavering. We are confident that the Drill Bit Circular Saw will set a new standard for cutting tools and equip professionals with the means to elevate their work to the next level.For professionals who demand precision, efficiency, and reliability, the Drill Bit Circular Saw is the ultimate choice. Experience the future of cutting technology with our latest innovation.

Ultimate Guide to Choosing the Best Bandsaw for Your Woodworking Projects

Bandsaws have long been a staple tool in the woodworking and metalworking industries, and now {} is bringing their expertise to the forefront with their latest line of bandsaw models. With a commitment to quality, precision, and innovation, {} has become a trusted name in the power tool industry, and their bandsaws are no exception.One of the standout features of {} bandsaws is their durability. Constructed with high-quality materials and built to last, these bandsaws are designed to withstand the rigors of daily use in a professional workshop or manufacturing setting. Whether cutting through hardwood, metal, or other tough materials, {} bandsaws are up to the task, providing reliable and consistent performance with each use.In addition to their durability, {} bandsaws are also known for their precision. Equipped with advanced cutting technology and adjustable settings, these bandsaws allow users to make accurate and clean cuts, even when working with intricate designs or detailed patterns. This level of precision is essential for woodworkers and metalworkers who require a high degree of accuracy in their work, and {} bandsaws deliver on this front.Furthermore, {} bandsaws are designed with user convenience in mind. From their ergonomic designs to intuitive controls, these bandsaws are built to make the cutting process as smooth and efficient as possible. This not only improves the overall user experience but also allows for increased productivity in the workshop.In terms of innovation, {} is constantly pushing the boundaries with their bandsaw technology. By incorporating the latest advancements in the industry, such as improved blade designs and enhanced safety features, {} bandsaws are at the forefront of bandsaw innovation. This commitment to staying ahead of the curve ensures that {} customers are always working with the best and most efficient bandsaw technology available.Furthermore, {} offers a wide range of bandsaw models to suit the needs of different users. Whether a small, portable bandsaw for a hobbyist or a larger, industrial bandsaw for a professional workshop, {} has a bandsaw to fit the bill. This versatility has made {} a go-to choice for woodworkers and metalworkers of all levels.But {} bandsaws are not just about the tools themselves—they are backed by a company that is dedicated to customer satisfaction. With a focus on providing excellent customer service and support, {} is committed to helping their customers get the most out of their bandsaws. This includes offering comprehensive warranty coverage, as well as access to a knowledgeable support team that can assist with any questions or concerns that may arise.In conclusion, {} bandsaws are a top choice for anyone in need of a reliable, precise, and innovative bandsaw. With a focus on durability, precision, user convenience, and innovation, {} has established themselves as a leader in the bandsaw industry. Backed by a commitment to customer satisfaction, {} is a company that woodworkers and metalworkers can trust to deliver quality bandsaws that meet their needs.

Highly Efficient Saw Dust Machine for Your Woodworking Needs

Saw Dust Machine Revolutionizes Woodworking IndustryInnovative technology has once again changed the woodworking industry as a leading company introduces its revolutionary Saw Dust Machine. With the growing demand for efficient and sustainable solutions, this machine is set to transform the way sawdust is managed, benefiting both businesses and the environment.The Saw Dust Machine, developed by a team of experts at {Company Name}, is designed to effectively manage and process sawdust, a byproduct of wood processing. With its advanced features and cutting-edge design, this machine is set to revolutionize the woodworking industry, providing a sustainable and efficient solution for sawdust management.{Company Name} has been a pioneer in the field of woodworking machinery for decades, and the introduction of the Saw Dust Machine further solidifies its position as a leading innovator in the industry. The company's commitment to research and development has led to the creation of this game-changing machine, which is poised to make a significant impact on the woodworking sector.The Saw Dust Machine is capable of processing large volumes of sawdust, turning it into valuable material that can be used for various purposes. Whether it is used for fuel, animal bedding, or as a component in composite materials, the processed sawdust from this machine has numerous applications, providing a sustainable alternative to traditional disposal methods.One of the key features of the Saw Dust Machine is its efficiency in handling sawdust, significantly reducing waste and maximizing the utilization of this byproduct. This not only benefits woodworking businesses by creating additional revenue streams but also contributes to environmental sustainability by minimizing the impact of sawdust disposal.Additionally, the Saw Dust Machine is designed with user-friendly controls and safety features, ensuring that operators can efficiently and safely manage the processing of sawdust. Its robust construction and reliability make it a valuable asset for woodworking businesses of all sizes, providing a solution that meets the demands of modern woodworking operations.{Company Name} has introduced the Saw Dust Machine as part of its commitment to driving innovation and sustainability in the woodworking industry. By addressing the challenges associated with sawdust management, the company is helping businesses to adopt more sustainable practices while improving their operational efficiency.Furthermore, the Saw Dust Machine is a testament to {Company Name}'s dedication to delivering cutting-edge solutions that enable its customers to stay ahead in a rapidly evolving industry. The machine's introduction is aligned with the company's mission to provide reliable, high-quality machinery that meets the needs of woodworking businesses, while also contributing to environmental conservation efforts.As the woodworking industry continues to evolve, the introduction of the Saw Dust Machine represents a significant step forward in addressing the challenges of sawdust management. Its innovative design and sustainable approach demonstrate {Company Name}'s commitment to driving positive change in the industry, setting a new standard for sawdust processing and management.With the Saw Dust Machine, {Company Name} is empowering woodworking businesses to embrace a more sustainable and efficient approach to sawdust management, ultimately benefiting both the industry and the environment. As businesses seek to enhance their operations and minimize their environmental footprint, this revolutionary machine is set to play a pivotal role in shaping the future of the woodworking sector.

High-Quality Edge Banding Machines from Russia: A comprehensive guide

Russia has recently developed a new edge banding machine that is set to revolutionize the woodworking industry. This cutting-edge technology is expected to increase efficiency and productivity in the manufacturing process, making it a game-changer for woodworking companies around the world.The edge banding machine, developed by a leading Russian manufacturing company, is designed to apply edge banding to wood panels with precision and speed. This new technology boasts advanced features that set it apart from traditional edge banding machines, making it an attractive option for woodworking companies looking to streamline their production process.One of the key features of the new edge banding machine is its ability to handle a wide range of edge banding materials, including PVC, ABS, and wood veneer. This versatile capability allows woodworking companies to work with different types of materials, offering them greater flexibility in their production processes.In addition, the edge banding machine is equipped with advanced automation technology, allowing for smooth and efficient operation. This automation not only increases the speed of production but also ensures consistent and high-quality results, meeting the demands of modern manufacturing standards.Furthermore, the edge banding machine is designed with user-friendly controls, making it easy for operators to set up and operate the machine. This intuitive interface reduces the learning curve for new users, allowing woodworking companies to maximize the machine's potential from the get-go.Another standout feature of the new edge banding machine is its durability and reliability. Built with high-quality materials and precision engineering, this machine is designed to withstand the rigors of heavy-duty production in woodworking facilities. This means that companies can rely on the machine to perform consistently and deliver results over the long term.The Russian manufacturing company behind this innovative edge banding machine has a strong track record in producing high-quality woodworking machinery. With a focus on innovation and customer satisfaction, the company has established itself as a leader in the industry, continually pushing the boundaries of what is possible in woodworking technology.The company's commitment to research and development has led to the creation of this groundbreaking edge banding machine, which is poised to make a significant impact on the global woodworking market. By leveraging its expertise and experience, the company has succeeded in developing a product that addresses the needs of modern woodworking companies, offering a solution that combines efficiency, versatility, and reliability in one powerful package.As woodworking companies strive to keep up with growing demand and evolving industry standards, the new edge banding machine from Russia presents an opportunity to enhance their production capabilities and stay ahead of the competition. With its advanced features, user-friendly design, and reputation for quality, this machine is set to become a valuable asset for woodworking companies looking to elevate their manufacturing processes.In conclusion, the new edge banding machine from Russia represents a significant advancement in woodworking technology, offering a range of features and capabilities that promise to transform the way wood panels are finished. With its versatility, automation, durability, and user-friendly design, this machine is well-positioned to make a lasting impact on the woodworking industry, providing companies with the tools they need to thrive in today's competitive market.

Guide to Edge Banding for Furniture and Cabinets: Everything You Need to Know

- Edge banding is a process that involves covering the exposed sides of materials such as plywood, particleboard, or MDF with a thin strip of material to create a finished look. This process not only improves the appearance of the material but also provides protection from moisture and other environmental factors.One of the leading edge banding companies in the industry is {}. With a strong focus on innovation and quality, {} has been providing edge banding solutions to a wide range of industries including furniture manufacturing, interior design, and woodworking.{} offers a variety of edge banding materials including PVC, ABS, PMMA, and wood veneer. These materials come in different thicknesses, widths, and colors to suit the specific requirements of each customer. In addition to standard edge banding materials, {} also offers custom solutions for unique applications.The production process at {} is carefully monitored to ensure that the edge banding materials meet the highest standards of quality. Advanced manufacturing technologies and strict quality control measures are in place to guarantee consistent and reliable performance of the edge banding products.In addition to the standard edge banding materials, {} also provides value-added services such as custom color matching, pre-finished edges, and special finishes. These services allow customers to achieve a unique and customized look for their products while saving time and labor costs.With a strong commitment to sustainability, {} also offers eco-friendly edge banding materials that are free of harmful substances and environmentally safe. This allows customers to meet their sustainability goals without compromising on the quality and performance of the edge banding materials.In order to meet the growing demand for edge banding solutions, {} has expanded its production capacity and distribution network. This allows the company to offer competitive lead times and reliable delivery to customers around the world.As a customer-centric company, {} places a strong emphasis on customer service and support. The company’s experienced sales and technical team is dedicated to providing personalized assistance to customers throughout the entire process, from product selection to after-sales support.With a proven track record of delivering high-quality edge banding solutions, {} has built a strong reputation in the industry. The company’s edge banding materials are widely used by furniture manufacturers, interior designers, and woodworking professionals around the world.As the demand for customizable and high-quality edge banding materials continues to grow, {} remains at the forefront of the industry with its innovative products, reliable performance, and exceptional customer service. With a focus on quality, innovation, and sustainability, {} is well-positioned to meet the evolving needs of its customers and maintain its leadership in the edge banding industry.

Affordable and Efficient Mini Lathe Machine for Your Workshop

Mini Lathe Machine, the latest addition to the impressive line of products offered by {company name}, is set to revolutionize the small-scale machining industry. With its compact size and powerful capabilities, this mini lathe machine is designed to meet the needs of hobbyists, small workshops, and educational institutions.Established in 1998, {company name} has been a leading manufacturer and supplier of precision machinery and equipment. With a mission to provide high-quality products and exceptional customer service, the company has continuously innovated and expanded its product range to meet the evolving needs of its customers.The Mini Lathe Machine is a testament to {company name}'s commitment to delivering cutting-edge solutions to the machining industry. With a maximum cutting diameter of 180mm and a distance between centers of 300mm, this machine is capable of handling a wide range of machining projects. It features a powerful motor that provides ample torque for turning, drilling, and threading operations. Additionally, the machine is equipped with a digital readout system that allows for precise and accurate measurements, ensuring the highest level of precision in every project.One of the key features of the Mini Lathe Machine is its compact size, making it ideal for use in small workshops and spaces with limited room. Despite its small footprint, the machine does not compromise on performance, making it an ideal choice for hobbyists and professionals alike. Its user-friendly interface and intuitive controls make it easy to operate, ensuring that even beginners can quickly master its functionality.In addition to its impressive technical specifications, the Mini Lathe Machine is also designed with safety and durability in mind. It is built with high-quality materials and components, ensuring reliable performance and longevity. Furthermore, it is equipped with safety features such as emergency stop buttons and protective guards, providing users with peace of mind as they work on their projects.The Mini Lathe Machine is already making waves in the small-scale machining industry, receiving rave reviews from hobbyists and professionals who have had the opportunity to use it. Its ability to handle a wide range of materials, from wood and plastic to various metals, has made it a versatile tool for a myriad of applications. Whether it's creating intricate designs on metal or turning wooden parts for a project, this machine delivers consistent and precise results every time.{Company name} has also ensured that customers receive all the support they need to make the most of their Mini Lathe Machine. From comprehensive user manuals to responsive customer service, the company is dedicated to ensuring that every customer has a seamless experience with their product. Additionally, they offer a range of accessories and spare parts to complement the machine, providing users with the flexibility to customize it according to their specific needs.In conclusion, the Mini Lathe Machine from {company name} represents a game-changer in the small-scale machining industry. Its compact size, powerful capabilities, and user-friendly design make it a must-have for hobbyists, small workshops, and educational institutions. Backed by {company name}'s commitment to quality and customer satisfaction, this machine is set to empower users to bring their machining projects to life with precision and ease.

Exploring the Benefits of Melamine Edge in Enhancing Furniture Aesthetics

{Melamine Edge Manufacturer} Expands Production to Meet Increasing Demand[date][location] - In response to the surging demand for top-quality melamine edges, leading manufacturer [Melamine Edge Manufacturer] has announced an expansion of its production capabilities. With a focus on improving efficiency, increasing output, and meeting customer requirements, the company aims to further solidify its position as a trusted supplier of melamine edges in the market.Melamine edges are widely used in various applications, including furniture manufacturing, interior design, and construction. As a cost-effective alternative to natural wood, melamine edges offer a durable solution that enhances the aesthetics of different surfaces. As such, their popularity has been steadily growing, prompting [Melamine Edge Manufacturer] to ramp up production.With its commitment to delivering high-quality products, [Melamine Edge Manufacturer] has emerged as a reputable name in the industry. The company's dedication to precision, innovation, and customer satisfaction has won it a loyal customer base and enabled it to develop long-standing relationships with clients worldwide.One key factor contributing to [Melamine Edge Manufacturer]'s success is its state-of-the-art manufacturing facilities. Equipped with cutting-edge machinery and advanced technology, the company can produce melamine edges in various sizes, colors, and finishes to meet diverse customer demands. Its production process adheres to strict quality control measures to ensure the final product meets the highest industry standards.To accommodate the escalating demand, [Melamine Edge Manufacturer] has recently completed an extensive expansion of its production plant. The increased capacity will not only allow the company to meet current market demands but also prepare for future growth opportunities. By investing in advanced machinery and optimizing production workflows, [Melamine Edge Manufacturer] aims to improve efficiency and maintain a competitive edge in the industry.Additionally, the company's commitment to sustainability sets it apart. [Melamine Edge Manufacturer] follows environmentally friendly practices throughout its production process, ensuring minimal waste, energy efficiency, and responsible sourcing. By integrating sustainable principles into its operations, the company aims to contribute positively to the environment and the community in which it operates.As a result of these efforts, [Melamine Edge Manufacturer] has gained the trust of both domestic and international customers. Its products are widely distributed across the globe, in markets ranging from North America and Europe to Asia and beyond. The company's commitment to excellence has garnered recognition and accolades, further solidifying its position as an industry leader.The expansion of [Melamine Edge Manufacturer]'s production plant is expected to have a significant impact on its overall output capacity. The increased supply will alleviate the existing market strain and allow the company to fulfill orders promptly while maintaining its commitment to superior product quality.Moreover, the expansion carries promising implications for the local economy as well. The creation of new job opportunities will help stimulate economic growth in the region and provide a source of livelihood for many individuals. By investing in human resources and ensuring employee satisfaction, [Melamine Edge Manufacturer] demonstrates its commitment to social responsibility and community development.In conclusion, [Melamine Edge Manufacturer]'s recent expansion of its production capabilities reflects the company's commitment to meeting the increasing demand for high-quality melamine edges. Through its state-of-the-art facilities, commitment to sustainability, and dedication to excellence, [Melamine Edge Manufacturer] is well-positioned to maintain its status as a trusted supplier in the global market. The expansion not only benefits the company itself but also contributes to the growth of the local economy and the overall industry.

The Ultimate 5-in-1 Woodworking Machine for Your DIY Projects

Introducing the 5 In 1 Combination Woodworking Machine from [Company Name], your one-stop solution for all your woodworking needs. The [Company Name] has been a key player in the woodworking machinery industry for over 20 years, providing high-quality and innovative machines to workshops and manufacturing plants around the world. With a strong emphasis on customer satisfaction and product reliability, the [Company Name] has built a solid reputation as a trusted and leading manufacturer in the industry.The new 5 In 1 Combination Woodworking Machine is the latest addition to the [Company Name] product lineup, designed to streamline and optimize the woodworking process. This versatile and compact machine is a game-changer for woodworking enthusiasts and professionals alike, offering a range of functions in one convenient package. Whether you are a seasoned woodworker or just starting out, this machine is sure to enhance your productivity and precision in the workshop.So, what exactly does the 5 In 1 Combination Woodworking Machine offer? Firstly, it combines five essential woodworking functions into one unit, including a table saw, planer, thicknesser, spindle moulder, and mortiser. This means that users can tackle a variety of woodworking tasks without the need for multiple machines, saving both space and time in the workshop. The machine also boasts a powerful motor and precision engineering, ensuring smooth and accurate performance across all its functions.In addition to its functional versatility, the 5 In 1 Combination Woodworking Machine is also designed with user convenience in mind. It features intuitive controls, quick changeover capabilities, and safety features, making it easy and safe to operate for woodworkers of all skill levels. The machine is constructed from durable and high-quality materials, ensuring its longevity and reliability in demanding workshop environments.[Company Name] takes great pride in its commitment to customer satisfaction and support. Alongside the release of the 5 In 1 Combination Woodworking Machine, the company is also rolling out comprehensive training and support programs for users. This includes instructional materials, online resources, and dedicated customer service to assist with any inquiries or technical issues. With [Company Name], customers can have peace of mind knowing that they are supported every step of the way in their woodworking journey.The introduction of the 5 In 1 Combination Woodworking Machine is the result of [Company Name]'s ongoing dedication to innovation and excellence in the woodworking machinery industry. By listening to the needs and feedback of its customers, [Company Name] continues to push the boundaries of what is possible in woodworking technology. The 5 In 1 Combination Woodworking Machine is a testament to this commitment, delivering a solution that empowers woodworkers to work more efficiently and effectively.With its reliable performance, comprehensive support, and industry-leading innovation, the 5 In 1 Combination Woodworking Machine from [Company Name] is set to become an essential tool for woodworking professionals and hobbyists alike. Whether you are looking to expand your woodworking capabilities or streamline your workshop, this machine is sure to exceed your expectations and deliver exceptional results.In conclusion, the 5 In 1 Combination Woodworking Machine from [Company Name] is a game-changing addition to the woodworking industry, offering unparalleled versatility, convenience, and reliability. As [Company Name] continues to set the standard for woodworking machinery, customers can expect nothing but the best from this innovative and customer-focused company.

How to Choose the Best Edge Banding Machine for Your Needs

Innovative Edge Banding Machine Revolutionizing the Furniture IndustryThe furniture manufacturing industry has seen rapid advancements in recent years, with technology playing a critical role in improving efficiency, precision, and overall productivity. One such groundbreaking technology that has gained significant attention is the EVA Edge Banding Machine, developed and manufactured by a renowned industry leader.The EVA Edge Banding Machine is a state-of-the-art solution that promises to revolutionize the way furniture manufacturers apply edge banding materials to their products. With its advanced functionality, ease-of-use, and exceptional performance, this machine is set to become a game-changer in the industry.Designed to cater to the needs of both small-scale operations and larger production facilities, the EVA Edge Banding Machine boasts a range of features to ensure optimal results. It is equipped with cutting-edge technology that allows for precise and flawless edge banding application, delivering a seamless finish that enhances the overall aesthetics of the furniture piece.One of the key features of this remarkable machine is its ability to handle a wide variety of edge banding materials, including EVA (Ethylene-Vinyl Acetate) and PVC (Polyvinyl Chloride). This versatility enables furniture manufacturers to experiment and innovate with different materials, textures, and finishes, allowing for greater creative possibilities.Additionally, the EVA Edge Banding Machine incorporates advanced automation features, significantly reducing human error and improving production efficiency. The intelligent control system ensures consistent and accurate application of edge banding materials, eliminating the need for manual adjustments and saving valuable time during the manufacturing process.Not only does this innovative machine enhance productivity, but it also prioritizes safety and sustainability. The EVA Edge Banding Machine is equipped with a comprehensive range of safety features, all of which meet international standards and guidelines. This ensures a safe working environment for operators, minimizing the risk of accidents or injuries.Moreover, this cutting-edge technology promotes sustainability in the furniture manufacturing industry. The machine's efficient adhesive application system optimizes material usage, resulting in reduced waste. Additionally, it utilizes energy-saving mechanisms, reducing power consumption and contributing to a more eco-friendly production process.The company behind this groundbreaking technology has a rich history of excellence in the industry, with a strong commitment to innovation and customer satisfaction. With years of experience and expertise, they have established themselves as a trusted and reputable partner for furniture manufacturers worldwide.Committed to meeting the evolving needs of their customers, the company continuously invests in research and development, striving to bring the latest technological advancements to the market. This dedication to innovation has led to the creation of the EVA Edge Banding Machine, representing a significant milestone in the company's journey.Furthermore, the company offers a comprehensive customer support package, ensuring that manufacturers receive the necessary training and assistance to maximize the benefits of this cutting-edge technology. From installation and operation to troubleshooting and maintenance, their dedicated team of experts is readily available to provide guidance and support.With its exceptional performance, versatility, and commitment to sustainability, the EVA Edge Banding Machine is poised to transform the furniture manufacturing industry. This breakthrough technology not only streamlines production processes but also enables furniture manufacturers to deliver high-quality products that meet and exceed customer expectations.As the industry embraces this revolutionary edge banding machine, it is bound to inspire creativity, facilitate innovation, and revolutionize the way furniture is manufactured, marking a new era of efficiency and excellence in the industry.

Explore the Benefits of Woodworking CNC Machines

Title: Revolutionary Woodworking CNC Machine Unveiled, Paving the Way for Precision and EfficiencyIntroduction:In an era driven by technological advancements, manufacturing sectors have constantly sought innovative solutions to bolster productivity and improve the quality of their products. Addressing this demand for precision and efficiency, a renowned industry leader has introduced an advanced Woodworking CNC Machine that promises to redefine the woodworking landscape. This groundbreaking innovation is expected to revolutionize the industry, meeting the challenges faced by both professionals and enthusiasts alike.Company Overview:{The Company} is a globally recognized leader in manufacturing cutting-edge machinery for the woodworking industry. With years of experience and expertise, the company has consistently been at the forefront of innovation, delivering reliable and technologically advanced solutions to its customers. Their commitment to excellence, coupled with a customer-centric approach, has established {The Company} as a trusted name in the industry.Revolutionizing Woodworking:The recently unveiled Woodworking CNC Machine by {The Company} embodies a paradigm shift in the woodworking industry. Combining precision, efficiency, and versatility, this new offering has the potential to transform the way artisans, manufacturers, and hobbyists approach their woodworking projects.1. Precision Redefined:The Woodworking CNC Machine brings unparalleled precision to the wood crafting process. Equipped with state-of-the-art technology, including advanced sensors and automated controls, the machine ensures intricate cuts, meticulous shaping, and flawless finishes. This accuracy reduces material wastage, enabling woodworkers to optimize their resources and achieve consistent end products.2. Enhanced Efficiency:Boosting productivity is a key objective for any woodworking professional. The Woodworking CNC Machine achieves this with its efficient and time-saving features. Computer numerical control (CNC) capabilities enable operators to program and automate various woodworking operations, eliminating the need for manual intervention. This automation not only saves time but also minimizes the risk of errors, leading to enhanced overall efficiency.3. Versatility Unleashed:The Woodworking CNC Machine by {The Company} demonstrates remarkable versatility. With adaptable tooling options, it can perform a wide range of woodworking operations such as cutting, carving, engraving, and routing with remarkable precision. Moreover, it efficiently handles various types of wood, from softwoods to hardwoods and everything in between. Such versatility opens up endless possibilities for artisans, enabling them to explore their creativity without limitations.4. Advanced Safety Features:Safety is of paramount importance in any industry, and woodworking is no exception. {The Company}'s CNC Machine prioritizes user safety by incorporating advanced safety features. These measures include sensors that monitor tooling effectiveness, emergency stop buttons for quick response, and comprehensive safety protocols to minimize the risk of accidents. This emphasis on safety ensures a secure working environment, protecting both the user and the machine itself.Conclusion:With the advent of {The Company}'s revolutionary Woodworking CNC Machine, the woodworking industry has been given a powerful tool to bolster precision, efficiency, and productivity. This innovation embodies the company's commitment to customer satisfaction and its vision for shaping the future of woodworking. By simplifying complex woodworking processes, the CNC machine empowers professionals, hobbyists, and artisans to explore new horizons and elevate the quality of their creations. As the industry continues to evolve, tools like the Woodworking CNC Machine will set new benchmarks for excellence, ultimately driving the woodworking craft towards unprecedented possibilities.